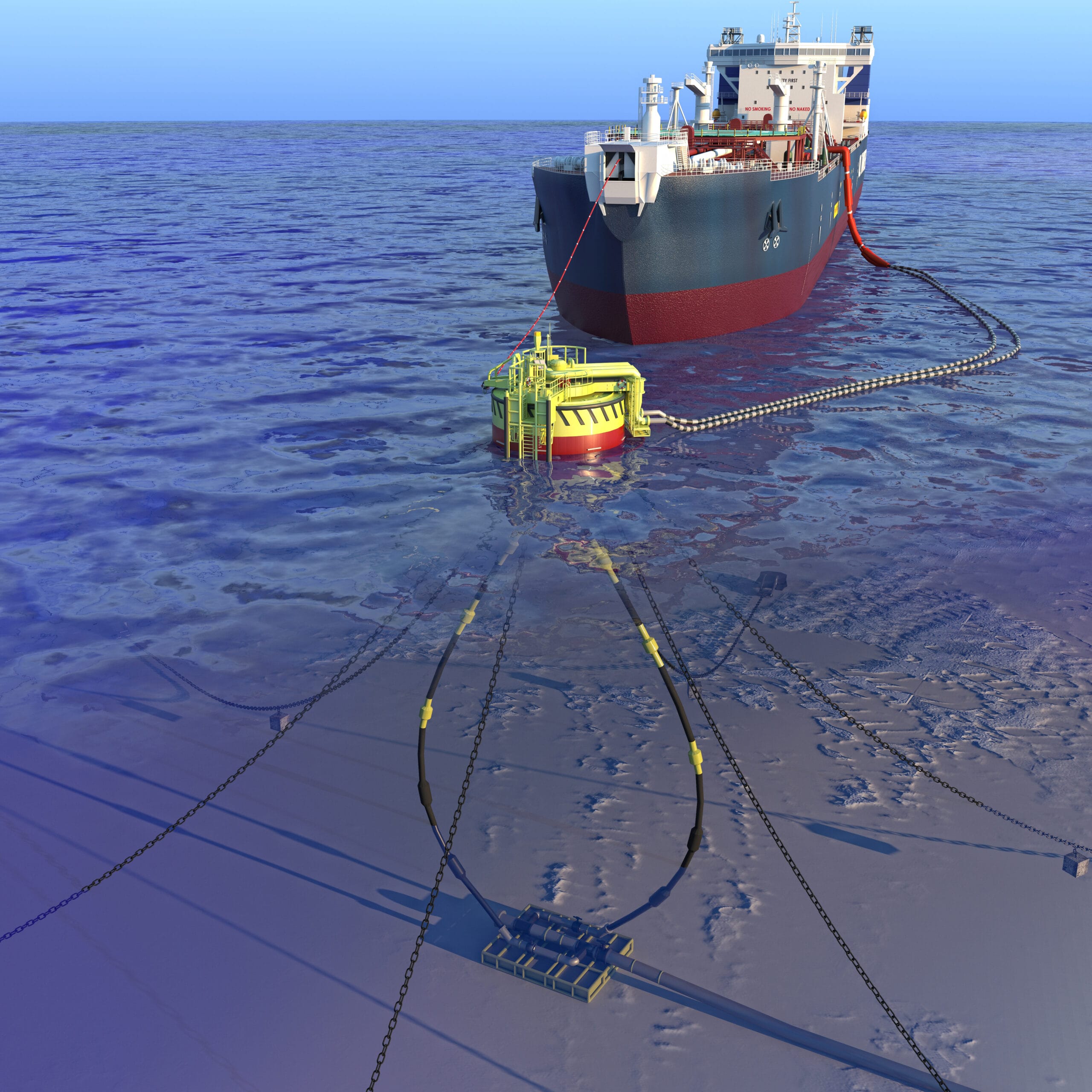

What is a Buoy to PLEM System?

A Buoy to PLEM (Pipeline End Manifold) system is an offshore oil and gas production system that is used to transport oil and gas from a floating production platform to an underwater pipeline end manifold (PLEM) on the seafloor. A buoy is moored to the seafloor using anchors and chains, and a flexible riser connects the buoy to the PLEM. The oil and gas produced by the floating platform is then transported through the flexible riser to the buoy, which serves as a connection point between the floating platform and the PLEM on the seafloor.

The Pipeline End Manifold is connected to the end of the pipeline on the seafloor. It serves as a connection point between the pipeline and the buoy, allowing oil and gas to be transferred from the buoy to the pipeline.

Advantages of Buoy to PLEM System

Cost-Effective

Buoy to PLEM systems are less expensive to install and operate than other offshore loading and unloading systems, such as fixed platforms and FPSO vessels.

Efficient

They are efficient in transferring fluids in different water depths and sea states and can be easily adapted to changes in demand.

Versatile

Buoy to PLEM systems are suitable for a range of offshore applications, including oil and gas production, offshore wind farms, and desalination plants.

Umbilicals for Buoy to PLEM Systems

Umbilicals for Buoy to PLEM systems are specialised cables or hoses that provide power, control and communication signals to subsea production equipment in offshore oil and gas fields. They are typically made up of multiple components, including electrical conductors, hydraulic hoses and fibre optic cables.

The umbilicals for Buoy to PLEM systems are used to transmit power and control signals from the production platform to the subsea production equipment, such as subsea wellheads, control valves and sensors. They also transmit data and communication signals, enabling real-time monitoring and control of the production system.

The umbilicals are designed to withstand the offshore environment which is notoriously harsh, and it includes high pressures, extreme temperatures, and corrosive fluids. High-strength materials such as steel or composite materials are used in their production, and are coated with specialised insulation and protection layers to ensure their durability and reliability.

Umbilicals for Buoy to PLEM systems can also be used to provide fluid injection, hydraulic power and chemical injection to the subsea production equipment, allowing for remote operation and control of the production system.

Considerations with Umbilicals for Buoy to PLEM Systems

Flexibility

Umbilicals for buoy to PLEM systems must be flexible enough to withstand the movement of the buoy and the PLEM.

Durability

Umbilicals for buoy to PLEM systems must be durable enough to withstand the harsh marine environment.

Corrosion Resistance

Umbilicals for buoy to PLEM systems must be resistant to corrosion from seawater and other marine pollutants.

Weight

Umbilicals for buoy to PLEM systems must be lightweight so that they can be easily deployed and retrieved.

Cost

Umbilicals for buoy to PLEM systems can be expensive, so it is important to choose the right umbilical for the application.